DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd., a leader in precision manufacturing, is pleased to announce the successful renewal of its ISO 9001:2015 (Quality Management Systems) and ISO 14001:2015 (Environmental Management Systems) certifications, following rigorous surveillance audits by the Beijing Zhong An Zhi Huan Certification Center. This achievement underscores our unwavering dedication to operational excellence, sustainable practices, and delivering superior value to our global clientele.

Comprehensive Certification Scope and Long-Term Validity

The renewed certifications, valid from December 3, 2024, to December 30, 2027, affirm our compliance across our core operations, encompassing the R&D, manufacturing, and sales of high-precision hardware components and our integrated environmental management activities.

Excellence in Precision Manufacturing & Quality Assurance

Our adherence to the ISO 9001 standard is a cornerstone of our business philosophy. This renewal validates our robust quality control framework, which governs our advanced CNC machining processes, stringent tolerance management, and continuous process optimization. It assures our partners in the automotive, industrial automation, and telecommunications sectors of our capability to consistently deliver components that meet the highest international standards for reliability and precision.

Proactive Environmental Stewardship & Sustainable Operations

Maintaining ISO 14001 certification reflects our proactive commitment to minimizing our environmental footprint. We have implemented systematic measures to enhance energy efficiency, optimize resource consumption, and manage waste streams within our precision manufacturing lifecycle. Initiatives such as advanced coolant recycling systems and comprehensive metal scrap recovery programs demonstrate our integration of environmental responsibility into daily operations, aligning with global sustainability goals.

Serving Demanding Global Industries

As a trusted partner for complex, mission-critical components, we serve sectors with the most stringent requirements, including aerospace, medical devices, and new energy equipment. These renewed certifications strengthen the foundation of trust with our clients, confirming that our technical expertise in advanced materials, complex geometry machining, and specialized surface treatments is backed by internationally recognized management systems.

A Foundation for Future Innovation

This successful recertification is a testament to the dedication of our entire team. Looking forward, DG Vifort will leverage this milestone to further invest in digital quality management platforms and explore synergies between smart manufacturing technologies and environmental performance, ensuring we remain at the forefront of the Industry 4.0 transformation.

Certification Details

Quality Management System Certificate No.: 02821Q11520R1S

Environmental Management System Certificate No.: 02821E10936R1S

Certification Body: Beijing Zhong An Zhi Huan Certification Center Co., Ltd.

Scope: Production and sales of precision hardware and associated environmental management.

Validity: December 3, 2024 – December 30, 2027

(Certificate authenticity can be verified via the official CNCA website or by scanning the QR codes on the certificates.)

About DG Vifort Precision Manufacturing Ltd.

Specializing in high-precision metal component fabrication, DG Vifort is equipped with state-of-the-art CNC machining centers, precision metrology equipment, and a comprehensive quality assurance system. We are committed to being a reliable and innovative manufacturing partner for the global advanced engineering sector.

Release Date: December 8, 2025

For media inquiries, please contact: [Michael Yan/Contact Person, anguzg@163.com]

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

DG Vifort Precision Manufacturing Ltd. Successfully Renews ISO 9001:2015 & ISO 14001:2015 Certifications, Reinforcing Commitment to Quality and Sustainability

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Surface Treatments for Precision Fasteners – Performance, Cost, and Selection Analysis (2025 Final Edition)

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

Process Innovation for Custom and Non-standard Fasteners — Cold Forging for Higher Efficiency and Lower Cost

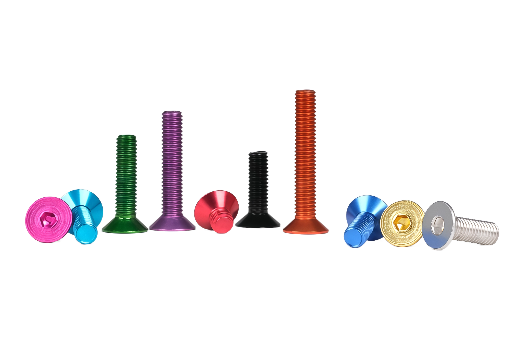

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications

News | 6061-T6 Aluminum Alloy Screws – Customer Requirements and Applications